How To Repair Crankshaft Journals

A racing crankshaft isn't necessarily a dispensable component – As seen in Elevate Racing Scene magazine.

Racing cranks adhere to the tightest tolerances. Typically, the machined surfaces on today's racing crankshafts are held to a .0003-inch (or amend) tolerance right out of the manufacturer's box. Those precision ground tolerances provide splendid load-carrying surfaces leading to a longer life for the creepo and bearing surfaces under the massive torsional load they endure in a racing application.

In the realm of drag racing, the stress imposed on a crankshaft is incredible when converting the radial forces from the piston and rod to the rotating motility of the crankshaft. The all-time materials and machining tolerances in your engine components are at war with the abuses of high rpm, clutches, torque converters, and launches. The list of crankshaft-hating scenarios goes on and on.

The failure of a rod or journal bearing is the most common calamity in the torturous bottom terminate of a racing engine. Other mutual failures include the thrust bearing area, typically located on the rear journal of the block. The crankshaft itself tin can incur damage without bearing failure. Full general wear of the crankshaft surfaces tin go outside of tolerable dimensions, and cracks or angle can take place.

Before you go and toss that damaged high-dollar crankshaft into the scrap heap, there are very viable repair techniques for these described scenarios. Of class, the simplest repair is to regrind the typical rod and main journal to a smaller bore, thus cleaning upwardly the damage.

Though bearings are readily available to compensate for the reduced crank journal bore after a "regrind," many debate the forcefulness of a crankshaft beyond the typical .010/.010 clean-upward. We will relieve that debate for another tech article.

The pre-heating and postal service-heating processes are unlike between brands and crank fabric with Ohio Crank's multiple ovens. Each crank is handled differently for the best outcome.

In that location are reputable crankshaft specialists similar Ohio Crankshaft who have the skills and machinery to repair your expensive crankshafts so they alive to fight another day. Ohio Crankshaft not only stocks more than 1,200 crankshafts for motorsport and hot rod applications, but they also audit and repair hundreds of crankshafts per twelvemonth. Their crank repair reputation ranges from motorsports to mega-sized cranks for agriculture and industrial applications. Ohio Crankshaft is also relied upon by many leading automobile restorers to resurrect irreplaceable vintage crankshafts.

"Racing crankshafts are reasonably straightforward when it comes to material and hardening processes used," Ohio Crankshaft owner Stan Ray explains. "Nosotros also repair crankshafts ranging from huge air compressors, to 7 1/2 feet long Allison aircraft engine cranks, to WWll aircraft. Some of these repairs get tricky with unique materials and hardening processes. We have mastered many welding and heat treating processes over the years for so many dissimilar crank materials."

Ray recommends the offset pace in crankshaft repair is the assay of the damaged unit of measurement.

"We always recommend the customer gives the states a call to describe in item what kind of crankshaft they have and what general harm it has before spending the dollars in shipping," Ray continues. "Though we can successfully repair some pretty severe damage, we merely detest to see someone spend the money to ship us a crank that is beyond repair. More importantly, nosotros can usually listen to what kind of crankshaft they take, along with the damage description, and derive if we can repair it. Today's digital photos and email tin can help us be spot-on with repair diagnosis too."

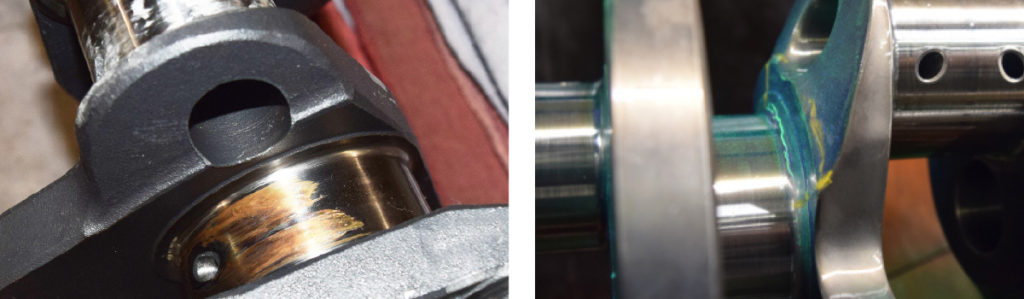

Once a crank arrives it is given a thorough inspection through magnetic particle testing, popularly known as the "Magnaflux" process. A ring of electric current produces a magnetic field around the crankshaft. A liquid solution containing fine fe powder flows over the crankshaft. A crack in the metal will disrupt the magnetic field, thus concentrating the liquid/metal mix at the crack. An ultraviolet black low-cal conspicuously illuminates whatsoever cracks typically invisible to the naked heart.

We followed Ray Darner through the repair procedure. Darner has more than 30 years of experience in crankshaft grinding and repair at Ohio Crankshaft.

"The entire repair process is based on knowing what procedure works best for each creepo we repair," Darner tells u.s.a.. "Unlike welding wire, welding heat, and welding speed are factored into every repair."

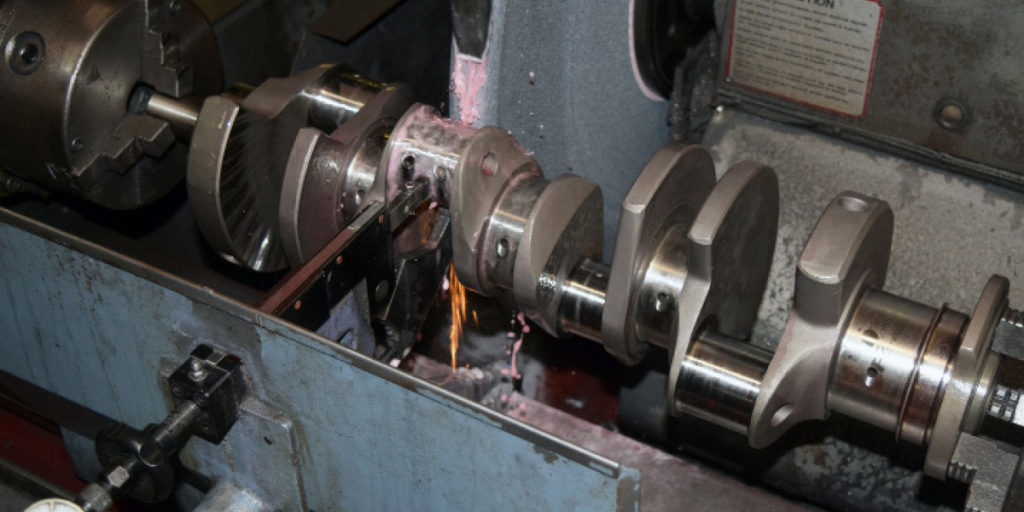

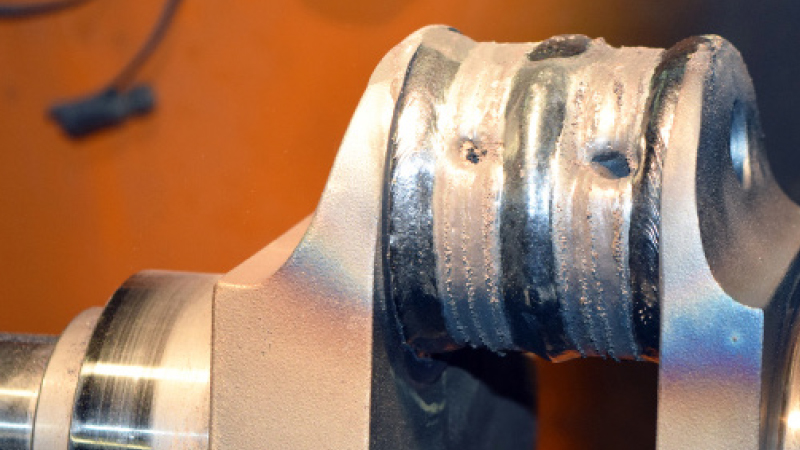

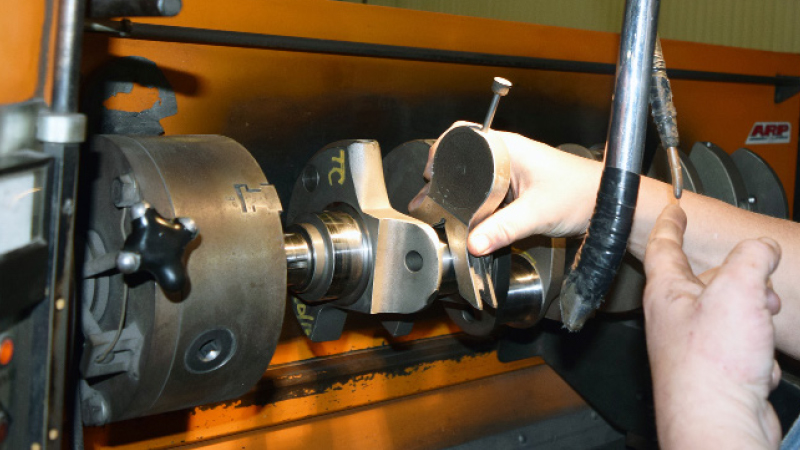

Before the welding process, the crankshaft surfaces to be welded are lightly ground to remove any strange materials, like bearing material, embedded in the crank. Creepo journals can as well be out of circular at the damaged surfaces, so this as well provides an even journal for welding.

At the welding station, Ohio Crankshaft uses "Submerged Arc" machinery considered to be the most effective way to go proper penetration of fabric build-up for re-machining. This welding procedure allows gravity-fed flux to completely cover the betoken of the arc from a loftier-amperage MIG welder. Equally with whatsoever welding procedure, a flux creates a gas that shields the welding arc from impurities in the full general air we exhale.

The welding auto is gear up similar to the crankshaft grinder. If a rod journal that rotates exterior of the crankshaft centerline requires welding, the welder is programmed to motion with the rod-stroke to go along an verbal distance betwixt the welder tip and the journal motion.

A metal liquid solution soaks the crankshaft while an ultraviolet black low-cal is shined on the inspected areas. The electric field is disrupted around whatever cracks, which concentrates the fine metallic particles, making any cracks visible that can't be seen by the naked middle (arrow).

"We pay shut attention to the straightness of the crank throughout the repair process," Darner describes. "From the beginning and throughout the welding and regrinding steps, we make certain the creepo remains dimensionally straight. We also pay very close attending to repairing of the radius at each side of a journal to the specs. This function of the repairing process is where experience pays off. Weld penetration can change between the journal face and the radiused ends. Knowing your various brands and material makeup of each crank pays off."

The straightening procedure is not exactly loftier tech, but the savvy straightening procedure is more than of an art than a science. The hydraulic crank press station is strategically located between the welding and grinding stations inside the Ohio Crankshaft facility. This station is filled with fixtures and multiple punch indicators that monitor many points along the length of the creepo. Hydraulic pressure is applied to "curve" the crank back to proper tolerances.

"This is where feel pays off," Darner smiles. "We know how much counter-angle is needed to any given crank and look information technology to render the proper tolerance. It'southward kinda similar baking cookies; you lot but get experienced in what it takes between a 5140, 4340, or barracks creepo to bring information technology back to straight in ane shot without going too far.

Magnetic particle testing, popularly known every bit the 'Magnafluxing,' happens when a band of electrical current produces a magnetic field around the crankshaft or any other metal engine component requiring inspection for cracks.

"Our feel goes into any heating of the crankshaft needed before and/or afterwards the repair procedure," Darner points out. "Depending on the crankshaft cloth and what kind of oestrus treating it had equally a new product, we follow whatever pre- or post-oven fourth dimension to hold the forcefulness information technology had from its manufacturer."

Great care goes into the starting point between the grinder and the welded surface, as not to be besides ambitious or put unnecessary heat into the welded surface area, but creepo welding and repair is condign a more feasible option when it comes to repairing a damaged engine to get back on the 'strip without breaking the banking concern.

How To Repair Crankshaft Journals,

Source: http://ohiocrank.com/save-the-crank/

Posted by: ferrisapere1969.blogspot.com

0 Response to "How To Repair Crankshaft Journals"

Post a Comment